My Experience with 3D Printing - Fraser Stewart

Published: 4 May 2017

I could write a blog about how fast the last few years of my PhD has gone, or the trials and tribulations along the way, but instead I’ve chosen to write about something that I have found particularly cool during my project. My topic of choice is 3D printing.

I could write a blog about how fast the last few years of my PhD has gone, or the trials and tribulations along the way, but instead I’ve chosen to write about something that I have found particularly cool during my project. My topic of choice is 3D printing.

So what exactly is 3D printing?

3D printed objects are created by adding subsequent layers of material in a position dictated by a 3D drawing of said object. This process of producing models is suitably known as additive manufacturing, as opposed to the more traditional manufacturing technique of subtractive manufacturing (where material is removed, not added). What I find fascinating about 3D printing is the range of materials that you can have printed these days, and how easy it is to have something printed. Companies online allow you to submit your model and choose printable materials such as: various plastics, resins, titanium, aluminium, steel, GOLD(!), bronze, ceramic, “rubber-like”, copper, WOOD?!, the list goes on…

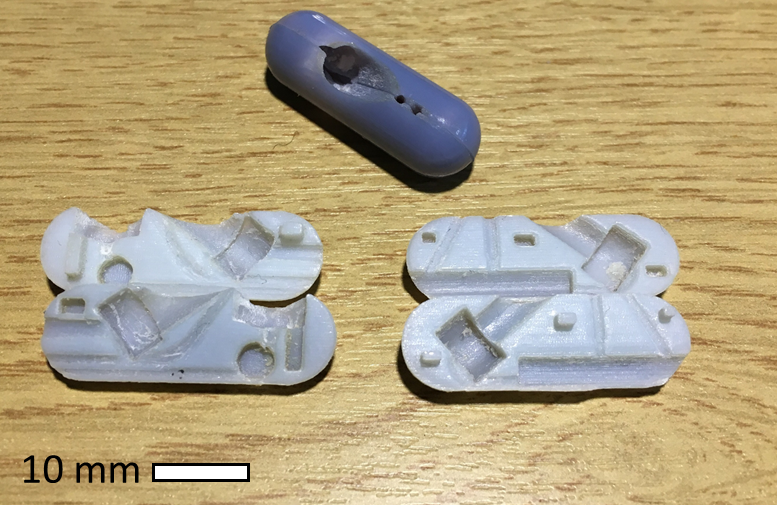

This pretty much allows us to print almost anything (see image below of some 3D printed capsules as an example). If you can draw it, you can (almost always) make it.

So what does 3D printing have to do with my project and Sonopill?

Good question. A lot. I have 3D printed various different things during my project, these include: capsule shells, transducer cases, various doo-dahs to hold equipment together, slide holders, bits of microscopes, etc etc…

In general, the things I have printed have usually been to hold equipment together that would otherwise be incompatible. One example of this has been a plate holder for a microscope stage. I contacted a company that makes them and they quoted ~£400, particularly pricey for a reasonably simple component. However, a 3D printed version of it cost around £20, not a bad saving I’d say…

To conclude, I’d say 3D printing is a valuable tool in research, every lab/division should have a 3D printer!

So that begs the question, what can’t we 3D print?

First published: 4 May 2017

<< Blog